For the project course Embedded Systems I had the opportunity to work with a most amazing team of Computer Science colleagues. We managed to build an impressive robot that peaked the interest of the examinations and we were awarded with a high grade.

My attributions for this project included designing the physical robot, 3D modelling and printing the necessary parts and programming the Arduino-based part of electronics, which represented the UX part of the project, but also the electrical interface with the various actuators and sensors.

I had the opportunity to be creative, to enhance my 3D printing and modelling skills, to work with electronics and sensors and to develop embedded software. Furthermore, by properly implementing SCRUM, I had a my first experience with working in a team in an organized and controlled manner.

Our project was meant to be built from FischerTechnik parts, the main focus being the design process and the programming itself.

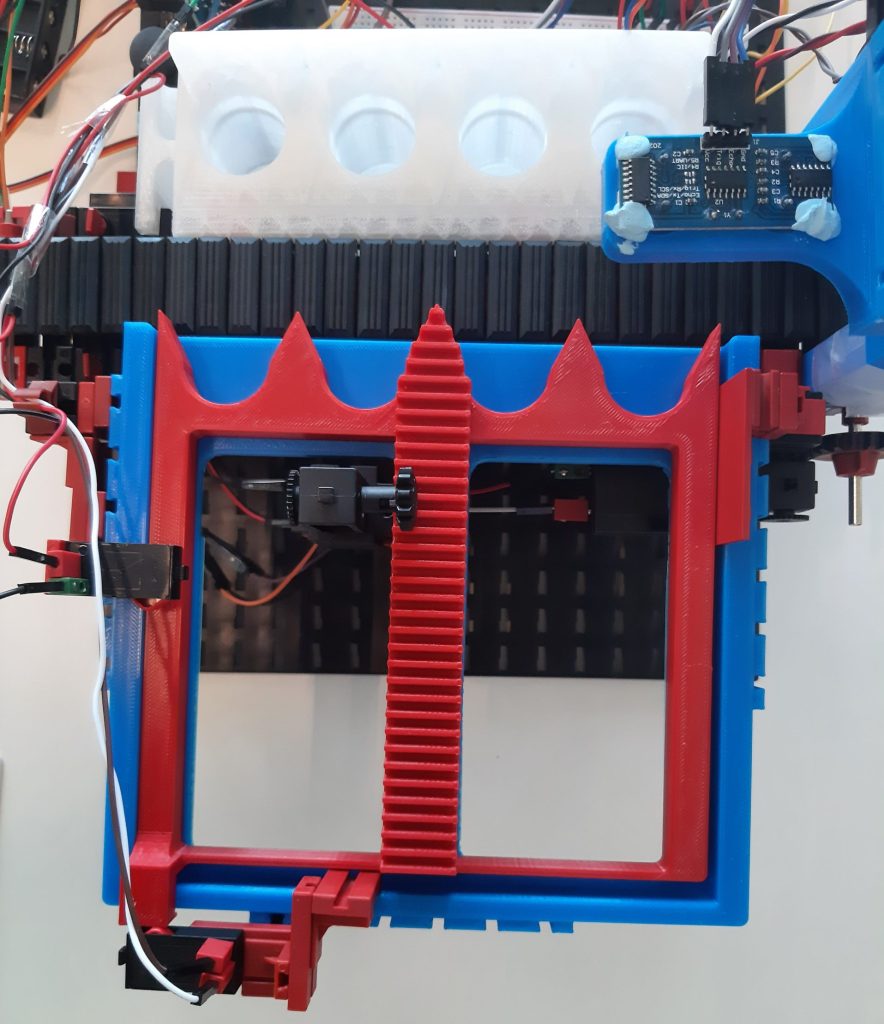

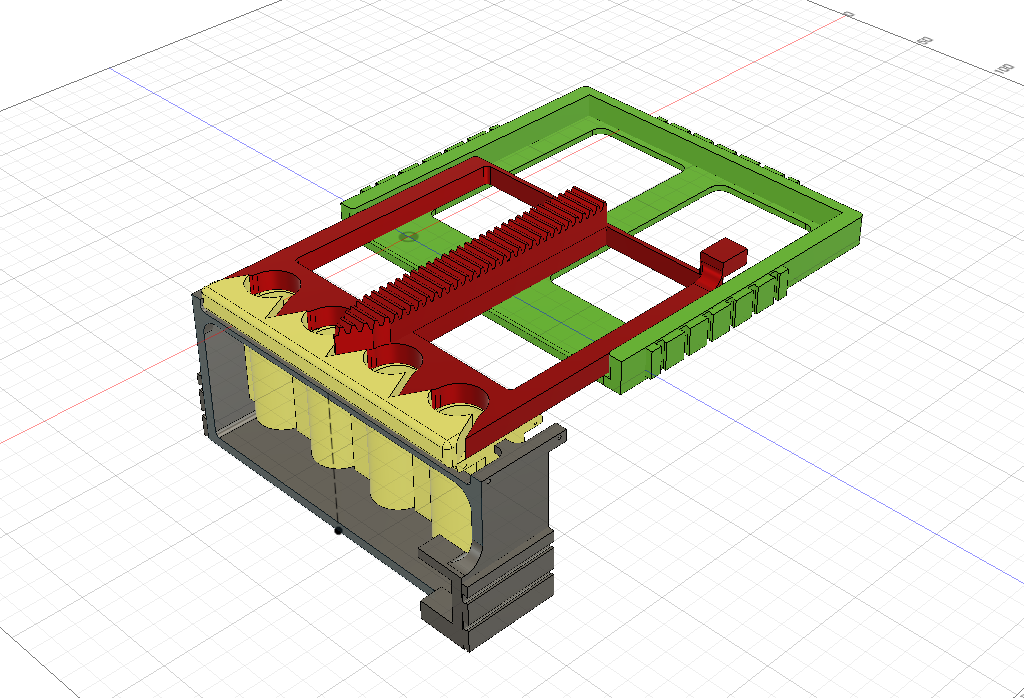

We have decided to go beyond what was offered and I have designed and manufactured custom parts for the robot. (the ones in red, blue and white). This allowed us to add extra functionality and offered us additional flexibility.

I have designed parts to be precisely compatible with the already present FischerTechnik parts, in a highly modular manner that allowed further design changes without the need of additional manufacturing.

Pictured are only the main mechanical parts of the project. I have also designed essential structural parts and various mounts for servos, the display and sensors.

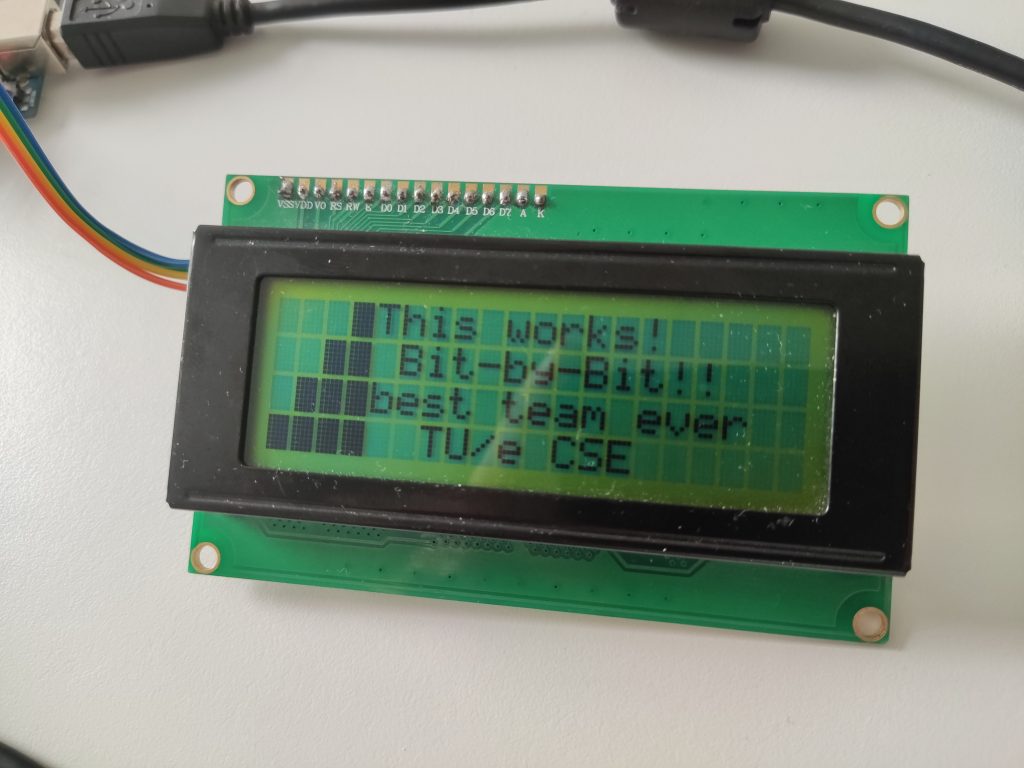

I have also designed the LCD UI. It is controlled by an Arduino that acts as a servant device to the main control board (a Raspberry Pi). The experience with the Arduino Space Shooter project that I built a few years prior helped tremendously, making the process seamless.

The Arduino also controls the motors and receives the input from the sensors, acting as an interface between the Pi and the electrical part of the project.

Everything I have designed has multiple layers of redundancy. From channels that self-center the pucks, to the shaking mechanism that makes sure they all lay flat.

Everything was designed in multiple iterations and perfected until the operation was flawless.

We have managed to obtain a nicely working product in the end. The video showcases it in an almost-finished state, before wire management and final sensor calibrations.